- 17.6.2025

Digital Twins: How and Why?

Digital twins are digital replicas of a real-world object like a town, factory, store or a human body. They represent the near real time status of the object giving insight on whatever variables you might want to monitor on the object. For example, if you want to monitor the status of your machinery in a factory you can build a digital twin where sensors of your machinery send data to your digital twin. On this digital twin you can monitor machinery status in a 3D representation and see exactly where your machinery might not be working optimally. You could even create alarms to capture failures before they even materialize. You could have a simple dashboard on the same data without a digital twin, but adding a 3D representation will give you a more intuitive view on the data. Instead of just reading data, you see where something is happening, making it easier to understand and act. And the bigger the subject is, the better benefits digital twins can offer to catch the whole picture or pinpoint some local issues.

Why Should I Have One?

Digital twins will give you a better view on the status of your subject. You might already have the data and alarms in place, but a digital twin provides you a clear picture where the issues are located. Let’s think of traffic monitoring: you can have a report where you can see the amount of cars and the speed of traffic on a report, but in a digital twin you can see the values on a 3D representation and you can see the chain of events and locate the bottle necks of the traffic. Besides traffic, you could monitor energy usage, water pipes etc.

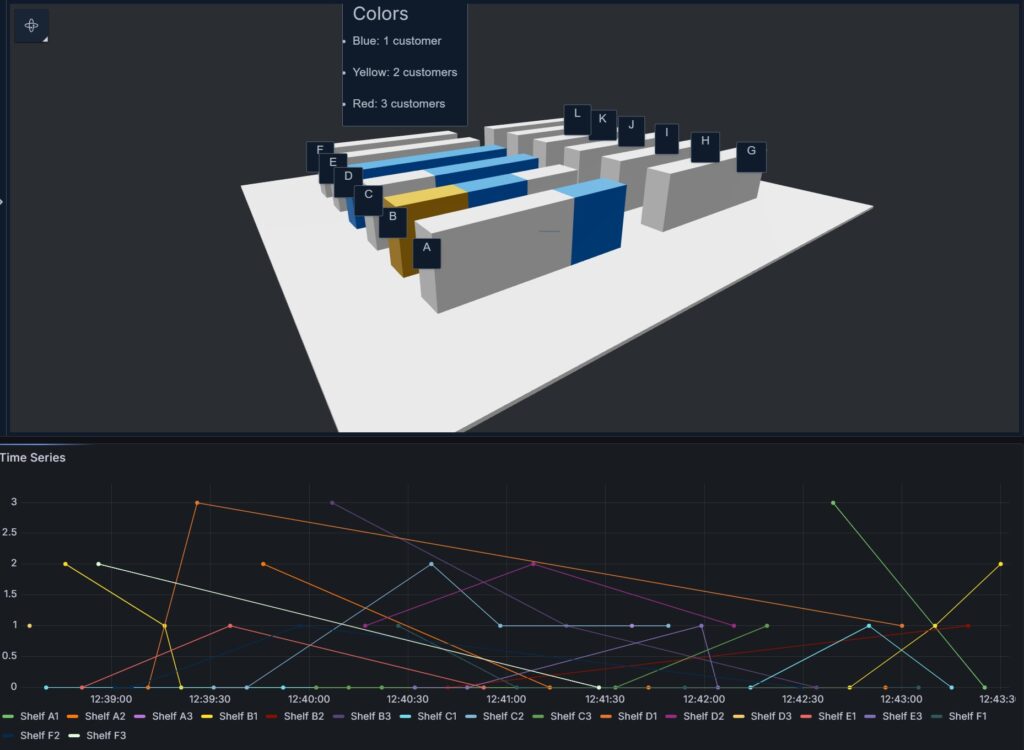

In a department store you can monitor customer flows inside the store, sales by the shelves or if the temperature of the cold shelves and freezers are within limits. Bakeries can monitor the temperature of their ovens, farmers can oversee the moisture and temperature of the soil. The use cases for digital twins are endless.

You can also monitor wear and tear of things like railway tracks, roads, airplanes, trucks Digital twins are even used in health care and sports to plan treatment or monitor drug responses or to mimic subject’s movement to improve techniques. You can access the digital twin onsite using a handheld device so you can check for example which machines need maintenance.

Adding AI to the mix allows you to predict maintenance needs, detect anomalies based on historical data etc, do simulation and scenario testing (traffic). For the use cases only imagination is the limit. And most importantly, digital twins look cool!

Implementation Made Easy

Implementing a digital twin might sound complicated and expensive, but today’s cloud services offer a simple and cost effective platform for implementing your digital twin. While this article focuses on AWS services, similar capabilities are available in Microsoft Azure and Google Cloud and they offer just as good a foundation for your digital twin journey.

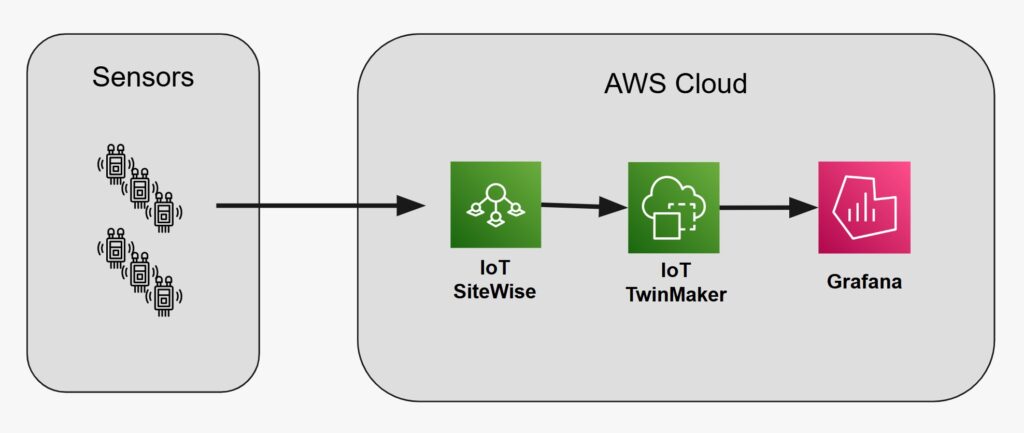

From an implementation point of view you need only the 3D model, some sensors or devices sending the data and a couple of AWS services. IoT SiteWise is used to capture the data that sensors are sending, IoT TwinMaker combines the data into the 3D model creating the actual digital twin and the actual dashboards are created by AWS Managed Grafana.

You might have an existing 3D model that you can use, but if not you can use tools like Blender to create one or use your precious bucks to have it made by some engineering office. I have to say that 3D modelling is its own expertise and creating fancy and detailed models is not that easy, but if you are fine with some Minecraft-style models, you could give Blender a go.

Capturing the Data

The sensor can be anything that provides measurements of your use case. IoT Sitewise can ingest data in various modes, including OPC-UA, AWS IoT Core or JSON/CSV data via SiteWise API. OPC-UA is an industrial standard method for low latency data transfer for edge devices widely used in on-premise industrial setups. AWS IoT Core captures data from remote or cloud-connected sensors and applications sending data to IoT Core topics. SiteWise API can be used to capture JSON/CSV data sent programmatically over HTTPS or to push batches of historical time-series data into SiteWise.

In SiteWise you define the model representing the sensor data, like a class in programming. This model describes the data of one type of sensor data. Under this model you define the assets, the actual sensors that are sending the data (like objects to a class). Asset describes the sensor attributes like sensor id and measurements (temperature, RPM, etc). SiteWise supports JSON imports of the assets so if you have lots of sensors you might want to go that way instead of defining them by hand in the console. TwinMaker is used to combine these SiteWise assets into the 3D model. You just need to define the entities and components in the TwinMaker workspace and you are ready to build your digital twin. Entities match the SiteWise assets and components provide the measurements of the asset. TwinMaker allows you to sync SiteWise source so it will automatically import SiteWise assets and create the entities and components for you based on SiteWise data, again helping much when having lots of sensors.

Building the Digital Twin

Once you have entities in place, you can start building your digital twin. Upload your 3D model and start building the scene and combining the incoming data into your 3D model. You can add annotations to show a value on a specific location on a 3D model, for example show rpm of a specific machine in a factory. Use different colors of a 3D model object based on some measurement or add icons like warning signs if some measurement goes beyond threshold. Set up motion indicators to show if something is moving inside a digital twin (like rotating engine) or define tags to highlight machines that need maintenance.

Once the TwinMaker scene is ready you can create an AWS Managed Grafana dashboard to provide end user access to digital twins. Grafana dashboard can be accessed via link or you can embed it to a web site.

And one more thing: set up proper IAM roles and policies and access control for Grafana. The usual stuff for all AWS solutions.

Final Thoughts

Digital Twins are no longer science fiction. With today’s cloud platforms simple twins can be built in a matter of days or weeks. Cloud services also have brought the costs down and if you already use cloud services, adding IoT to the mix is easier and more affordable than you might think. Start by identifying a use case and begin experimenting — your digital twin journey could be closer than you realize!

Links:

https://aws.amazon.com/iot-sitewise/